Alumina catalyst carrier extrudates for HDS,HDN,HDM

Alumina catalyst carrier shapes for hydrodesulfurization (HDS), hydrodenitrogenation (HDN), and hydrodemetallization (HDM):

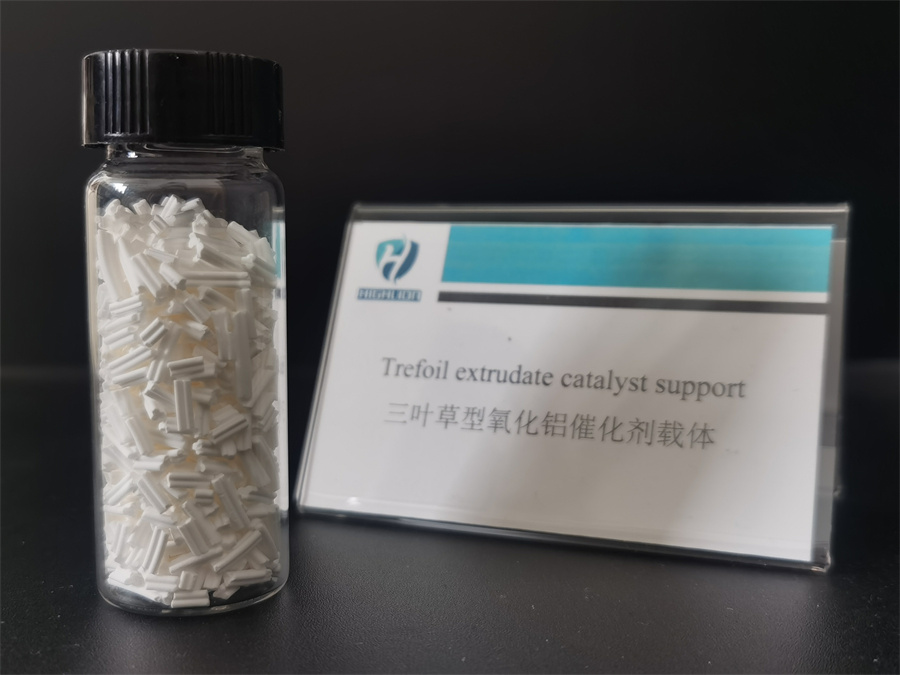

In hydrotreating processes for petroleum fractions, such as Hydrodesulfurization (HDS), Hydrodenitrogenation (HDN), and Hydrodemetallization (HDM), the most commonly used and dominant shape for alumina catalyst carriers is shaped extrudates, specifically trilobe(Trefoil, cloverleaf, three-lobe) or quadrilobe(4-lobe,four-lobe) shapes.

Here’s a detailed explanation and rationale:

1. Shaped Extrudates (Cloverleaf/Quadrilobe):

2. Cylindrical Extrudates:

3. Spheres:

Summary:

Preferred Shape: Cloverleaf-shaped (or similar shaped) extrudates. It perfectly balances high surface area, excellent tunability of pore structure, superior diffusion properties, sufficient mechanical strength, and acceptable bed pressure drop, making it the ideal carrier shape for HDS, HDN, HDM, and related processes.

Core Advantage: Optimized Diffusion.The increased external surface area and short diffusion paths of shaped extrudates are crucial for reactions involving large molecules (especially residue HDM) or those limited by internal diffusion (HDN, some HDS).

Size: Carrier particle diameters typically range from 1mm to 3mm (e.g., common sizes are 1.2mm, 1.3mm, 1.5mm, 3mm), with lengths several times the diameter. Specific dimensions are optimized based on feedstock properties (light/heavy), reactor design (pressure drop requirements), and process objectives.

Therefore, when referring to the shape of alumina carriers for HDS, HDN, and HDM catalysts, shaped extrudates (especially cloverleaf) is the standard answer.